RHINOX Stainless steel press fitting

There are a number of possible ways to join tubes and accessories in plumbing installations, including threaded joints, welding and inseparable joints using pressfitting of accessories (such as elbows, tees, couplings, etc.).

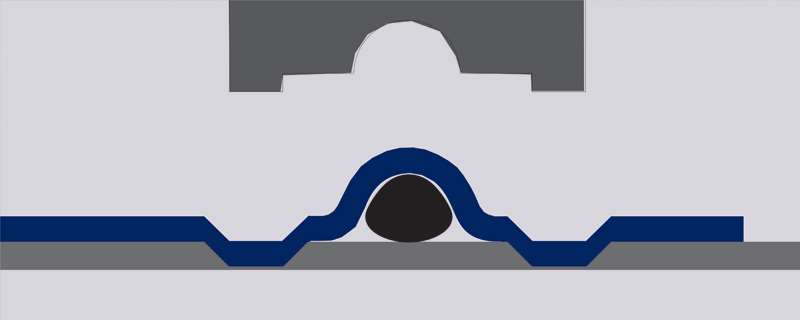

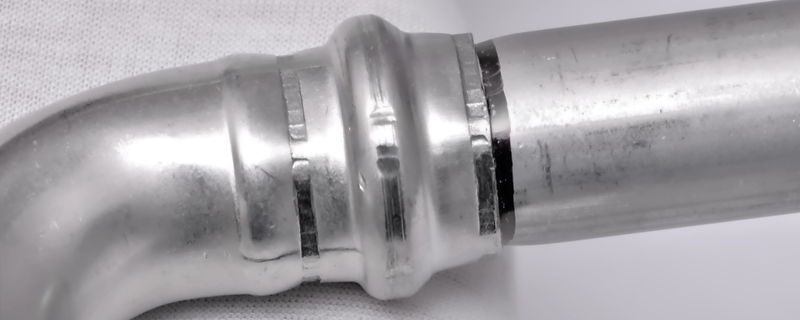

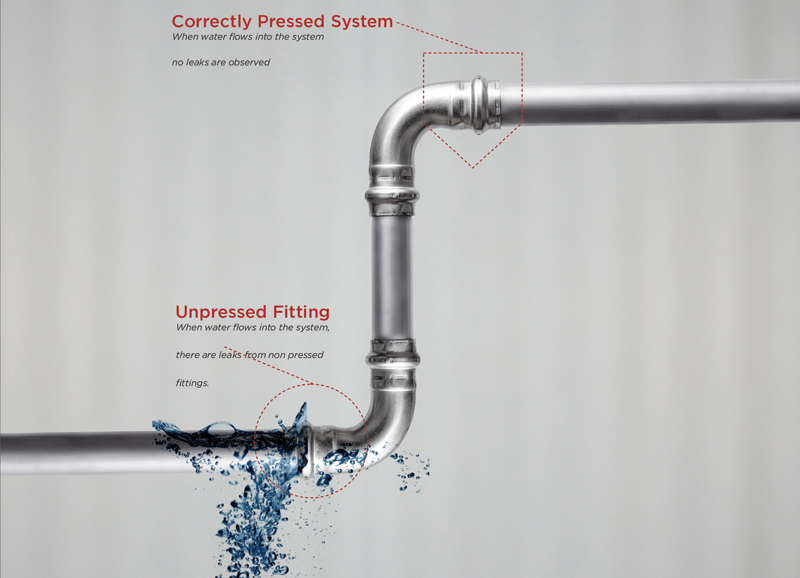

The Rhinox Pressfitting System - V Profile is an extremely fast and simple press fitting assembly system, producing reliable joints with high mechanical resistance for a wide variety of applications, from drinking water, gas, heating and solar installations to cooling water and compressed air systems. The resilience of the deformed seal rings ensures that the fittings are permanently and hydraulically leakproof. Corrosion-resistant, stainless-steel claws on the inside of the fitting ensure high tensile strength. Pressing and insertion are quick connection methods which save a lot of time in comparison to traditional methods such as soldering or welding.

V Press Fittings

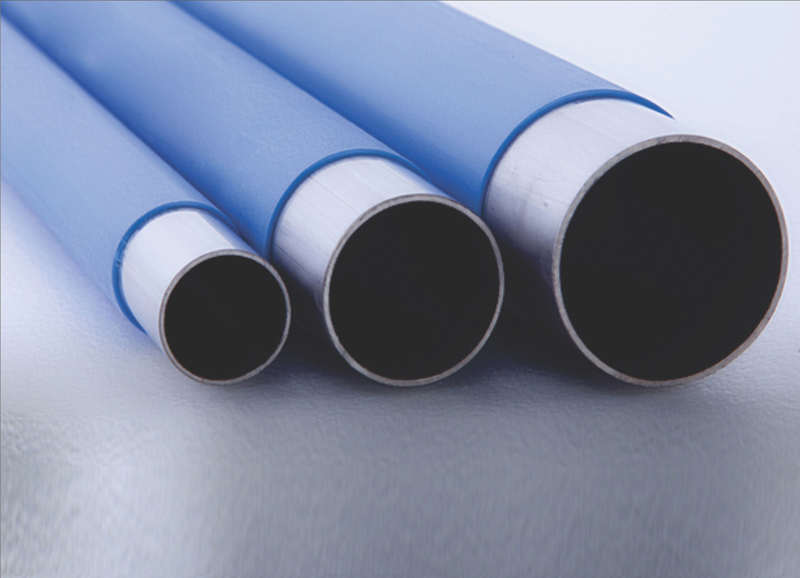

The RHINOX stainless steel installation system comprises of premium RHINOX system press fittings provided with a black EPDM sealing ring (ethylene-propylene-diene) rubber. All RHINOX press couplings are manufactured from the material coded 1.4404 / AISI 316L and 1.4408 (fittings with threaded end). The material coded 1.4404 / AISI 316L contains an increased molybdenum content of 2.3% molybdenum and a reduced carbon content, below the standard value of 1.4401. This has created a material that is not only equal in quality, but also possesses significantly greater resistance to corrosion.

RHINOX stainless steel press fittings in the 12 mm to 54 mm range are long-profile. The larger diameter material is designed with a short profile and can be fitted with an M-profile press tool only.

| APPLICATION RANGE | SIZE/PRESSURE/MARKING | SIZE/PRESSURE/MARKING | TOOLS |

|---|---|---|---|

| Drinking water | d = 12 - 108 mm | EPDM | d = 12 - 54 mm |

| Heating | maximum 16 bar | Colour: black | Choice of press tools and tongs or chains |

| Treated Water | Max. permanent temperature: -30 °C up to 120 °C | ||

| Cooling water | |||

| Dry compressed air | |||

| Industry | |||

| Sprinkler* | |||

| Fire extinguishing systems | |||

| download brochure | |||