Triple Press Fitting

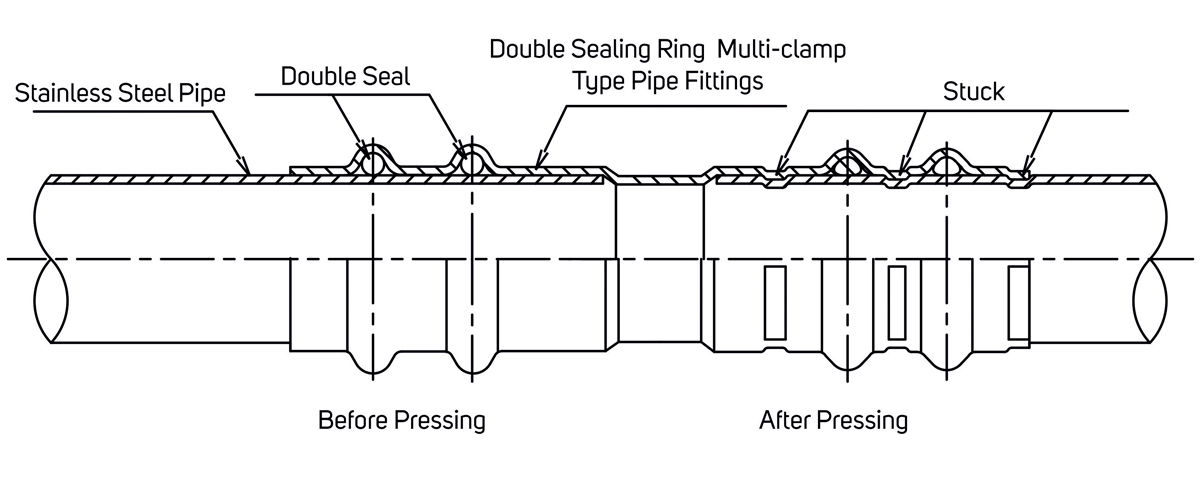

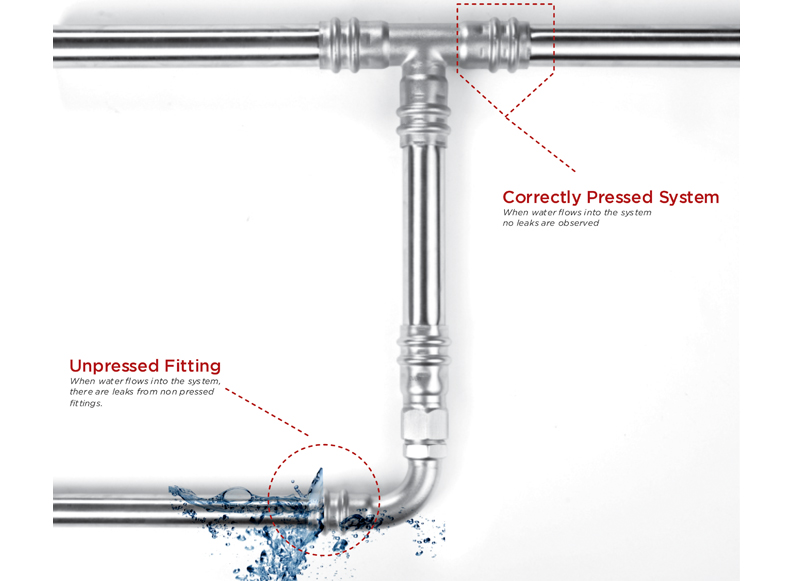

Rhinox stainless steel has been updated with a special profile which consist of double O-Ring with VV-shaped grooves, and 5 stage pressing. During the pipe connecting process, the special profile provides extraordinary safety function with double-edge. Adding the updated function of the safety edge on outside of the fitting prevent insufficient insertion. Moreover, if the fitting is un-pressed, the sealing ring with a lump allows the outflow of water drop and indicates un-pressed location. The compress-seizing method uses a special pressing tool to install Rhinox VV-press system.

Advantages include better hygiene, durability, less required maintenance, and cost savings, when taking into account the life cycle cost. Installation costs are also competitive. It delivers the best results when used with stainless steel press fittings, and is especially suitable for concealed location behind concrete wall or when laid underground.

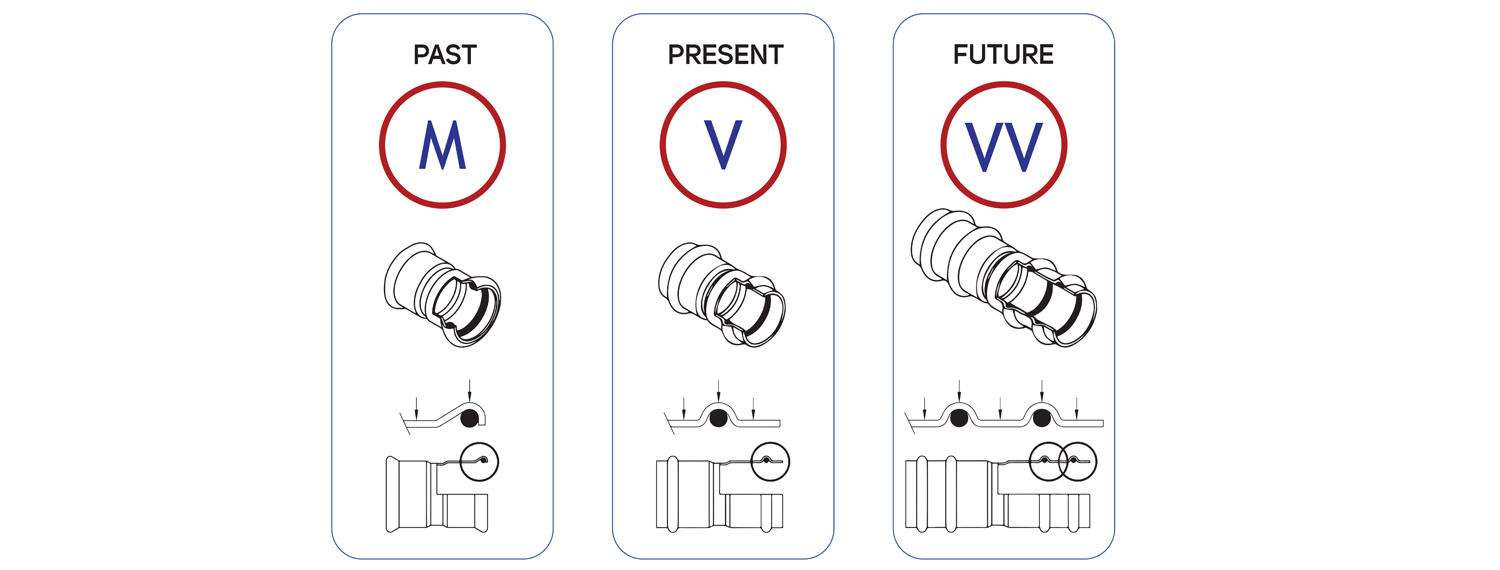

VV Press Fittings

There is difference in the press profile and the way the force is applied to the fittings when being pressed. As you will see in the above images, the "M" profile fitting allows for 2 press points, while the "V" Profile fitting allows for 3 and "VV" Profile allows for only 5 press points. This has a dramatic effect upon the overall security and pressure rating of the actual joint.

All manufacturers of press fittings use the same raw materials and are certified to the same standards. The biggest difference is the profile of the fittings and the tooling used. Based on all of this information, if you are looking for the maximum safety in any installation, "VV"Profile fittings is most reliable connection. So, the next time you have a project and decide to use Stainless Press, ensure you use the right product that is fit for purpose and offers you the greatest security for your workmanship. For expert advice on any installation, please refer to our technical department.