RHINOX - THE SYSTEM

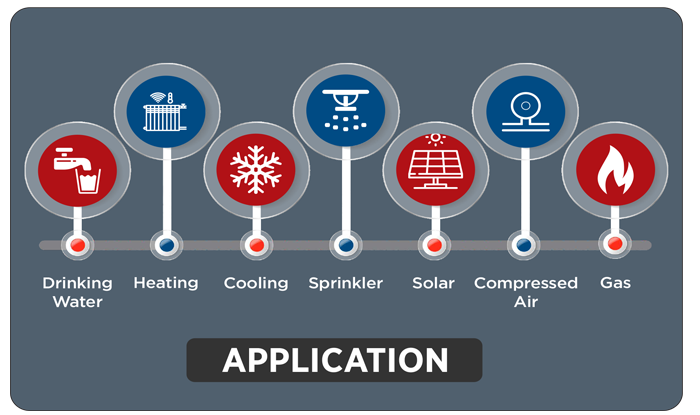

Rhinox is not just an ordinary fitting for a pipe connection. Rather, it is a combination of an innovative product, the associated tools and equipment, the service, the name and the simplicity of use, as well as the economic benefit. Rhinox is the leading, purely metallic, press connection system for the application area Drinking Water, sanitary water, Heating, cooling, Gas, Solar, Fire prevention, compressed Air and other industrial application The high-performance press fittings are developed for extremely high pressures and temperatures as well as a quick and secure press connection without the use of welding and flame onsite. The specially developed press tools always guarantee the same quality of each press connection in existing or new systems. A perfect connection in a few seconds.

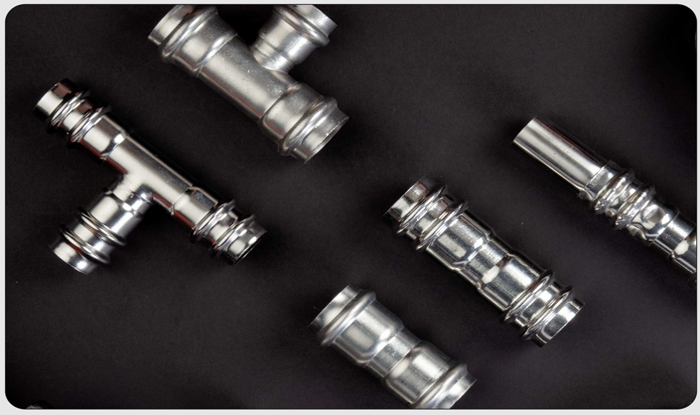

The RHINOX stainless steel installation system

comprises of premium RHINOX system V and VV

pres s fittings . All pres s couplings are

manufactured from the material coded 1.4404 /

AISI 316L (fittings with threaded end). The material

coded 1.4404 / AISI 316L contains an increased

molybdenum content of (>/-) 2.3% molybdenum and

a reduced carbon content. The RHINOX press system has been tested to

comply with industry standards USFDA, BSI

DVGW, NSF, WRAS, CE, HACCP, ROHS and

REACH certified by, the large International

certification institutes.

SYSTEM SUMMARY

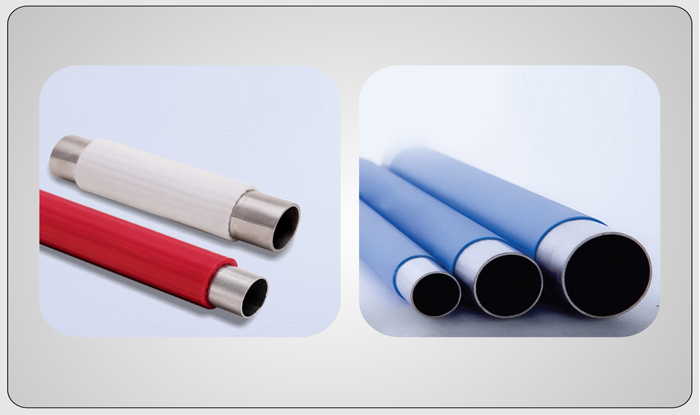

Stainless steel tubes are manufactured at the

highest level using autogenous (fusion)

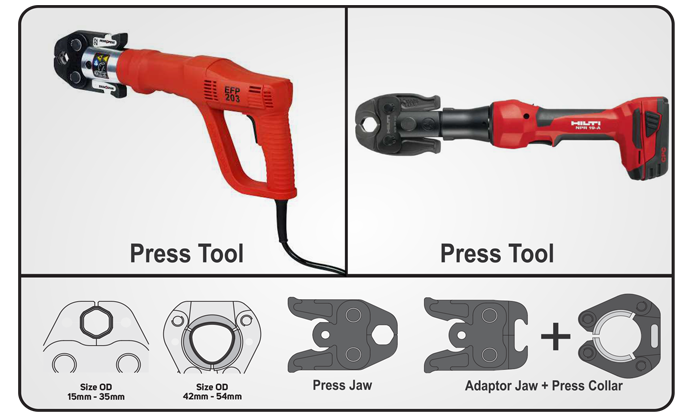

longitudinal gas tungsten welding processes. Standard size: in OD 15mm; 22mm; 28mm;

35mm; 42mm; 54mm, available with PE coated

and Pre-insulation which Heat-preserved, cool

preserved, wet resistant, dew resistant and prevent

the growth of wall carcinoma. The RHINOX press system has been tested to comply with industry standards USFDA, BSI DVGW, NSF, WRAS, CE, HACCP, ROHS and REACH certified by, the large International certification institutes.

TUBE

SIZE/MATERIAL

WORKING CONDITIONS

APPLICATION FIELD

PRESS TOOLS

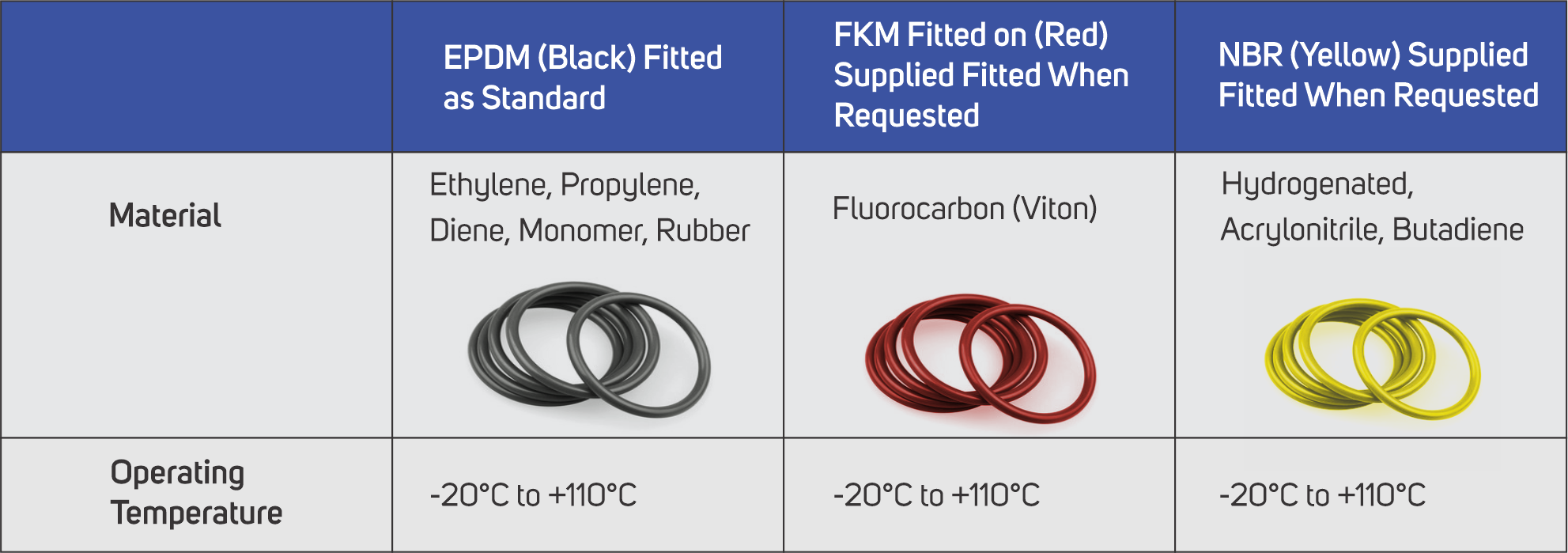

SEALING RING